Understand Lean Six Sigma as a “scalable infrastructure” and flexibly align it with organisational drivers and barriers.

- Training series for the flexible and demand-oriented application and implementation of Lean Six Sigma in practice

- Combining agile ways of thinking and working with the approaches of systematic process improvement

- Hybrid approach to combine agile building blocks with central cornerstones of the DMAIC cycle

- Develop accepted process improvements faster and bring them into implementation

- For Lean Six Sigma Belts (Green Belts, Black Belts, Master Black Belts)

- Part of the KEY VALUES Agile Circle

Agile for Lean Six Sigma

What is Agile for Lean Six Sigma?

As a Lean Six Sigma Belt (Green Belt, Black Belt, Master Black Belt), you use the tools and methods you have learned to improve processes in your projects in a targeted way to overcome the many challenges in your working environment. The implementation of the method in day-to-day business itself often becomes the real challenge, as Lean Six Sigma (LSS) project activities often start with great intentions and ultimately fail in the “nitty-gritty” of roles and responsibilities or are slowed down due to long durations and/or decreasing project priority.

The conviction and acceptance of employees for a jointly developed and implemented process improvement suffers as a result. LSS must therefore see itself as a “scalable infrastructure” that can be flexibly aligned with organisational drivers and barriers and support a Belt (Green Belt/Black Belt/Master Black Belt) to “pick up speed” – without loss of quality.

In this training series, the focus is on integrating agile building blocks into the DMAIC cycle in order to combine agile ways of thinking and working with the approaches of systematic process improvement according to Lean Six Sigma. However, the focus here is also on effective conflict management and prevention when implementing agile projects in “classic” project environments.

Our principles for Agile for Lean Six Sigma:

- More pull, less push

Lean Six Sigma does not need more methodological diversity “out of the watering can”, but rather success stories, both large and small, interest and acceptance in the teams - Speed without loss of quality

Use Lean Six Sigma as a “system” that can meet both central requirements of speed in execution AND quality in implementation - Less waterfall, more agility and flexibility

The DMAIC approach does not create a contradiction here – but our approach provides for a different timing of the DMAIC to allow for more agility and flexibility - More applicability and pragmatism, less textbook

Direct implementation of Lean Six Sigma should be issue- and team-focused and aligned with drivers and barriers of the organisation - A combination of WANT, MAY & CAN.

Project work should be designed in such a way that it is not a barrier, it does not tie up resources permanently and it generates tangible successes – acceptance is a key lever for success and speed

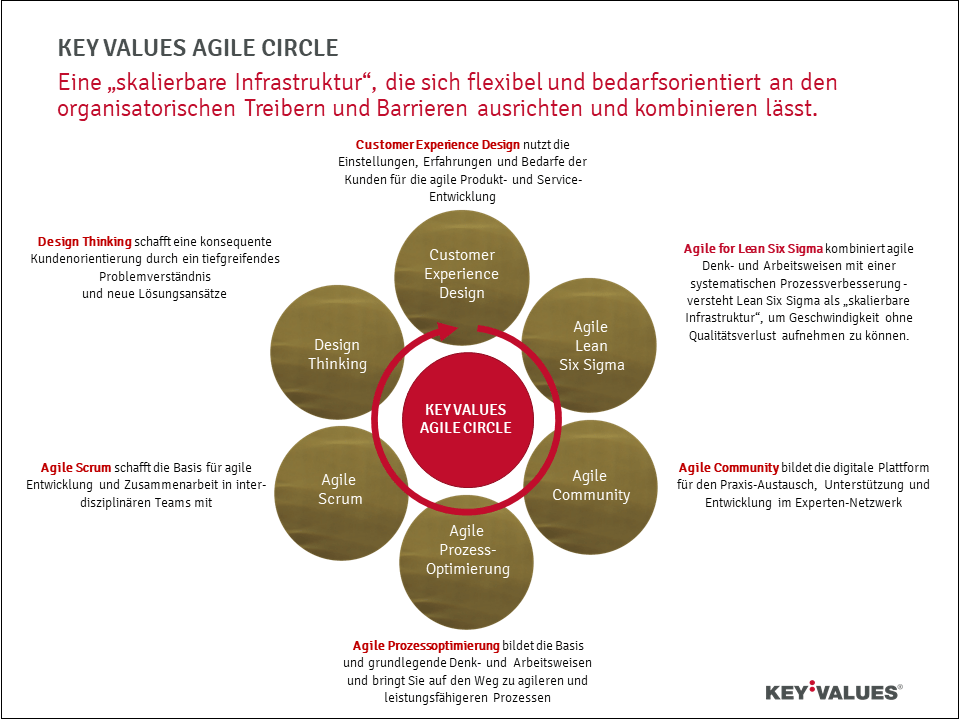

Agile for Lean Six Sigma is part of our KEY VALUES Agile Circle – a “scalable infrastructure” that develops competences in a targeted and needs-oriented way and in which appreciation, individual learning and value propositions are thought of in a new and different way and implemented in a concrete way.

What does Agile for Lean Six Sigma involve?

Agile for Lean Six Sigma is not “another training course to learn even more method”, nor is it “narrow track Six Sigma” or “abandoning process and data perspectives to accelerate project timelines”.

Our hybrid approach of agile working and process improvement is more paving the way for a problem- and organisation-oriented alignment of both ways of thinking and working and focuses on the following:

- Common understanding of important cornerstones of the DMAIC approach (tools and methods, red thread, project transfer, experience values)

- Common understanding of agile tools and methods (product vision, initial meeting, product backlog, user stories, sprints, daily scrum meetings, etc.)

- Hybrid approach to combining agile thinking and working methods with the approaches of systematic process improvement according to Lean Six Sigma

- Common understanding of targeted project preparation, agile implementation and team empowerment

- Creation of project roadmaps

- Elements of a project canvas and a driver and barrier analysis

- Elements of agile implementation (agile DMAIC setting, Gemba workshops, team empowerment etc.)

- Team empowerment through self-consulting, participation, self-responsibility, self-developed solutions on-the-job

- Conflict management and prevention in the implementation of agile projects in “classic” project environments

- Complementary approaches as tools and drivers for a hybrid approach (process mining for targeted ERP analysis, building a Belt community for best-practice sharing, standardised tools & roadmaps for efficient process and data analysis)

What are the advantages of Agile for Lean Six Sigma?

- You consistently apply the methodological knowledge you have learned from a Belt training series (Green Belt/ Black Belt/ Master Black Belt) and expand it to include new perspectives and possibilities

- You learn how to integrate agile building blocks into the DMAIC cycle and thus combine agile thinking and working methods with systematic process improvement

- You will learn how necessary resources in the project context can be relieved in a targeted way and still be involved

- You will experience how jointly supported process improvements can be developed and implemented more quickly

- You will not discuss process problems from the second row but directly “on the spot

- You learn how to achieve both more team empowerment and acceptance within the framework of their project

- You learn how conflict management and prevention can support the implementation of agile projects in “classic” project environments