Designing in a customer-oriented

and systematic way

- Re- and new design for products, processes and services

- Ideas become marketable innovations

- Reproducible red thread for innovation projects to always keep customer requirements in mind and avoid mistakes

- Globally practised and recognised method

- DfSS briefly explained: see video below

Design for Six Sigma (DfSS)

What is Design for Six Sigma?

Design for Six Sigma (DfSS for short) is a systematic navigation aid for innovation and development projects and ensures the path from the idea to a concrete and marketable innovation. The focus is on re-designs and new designs of products, processes and services, which are accompanied from the idea to the market launch in a customer-oriented manner. The method has become established in development practice.

What does Design for Six Sigma involve?

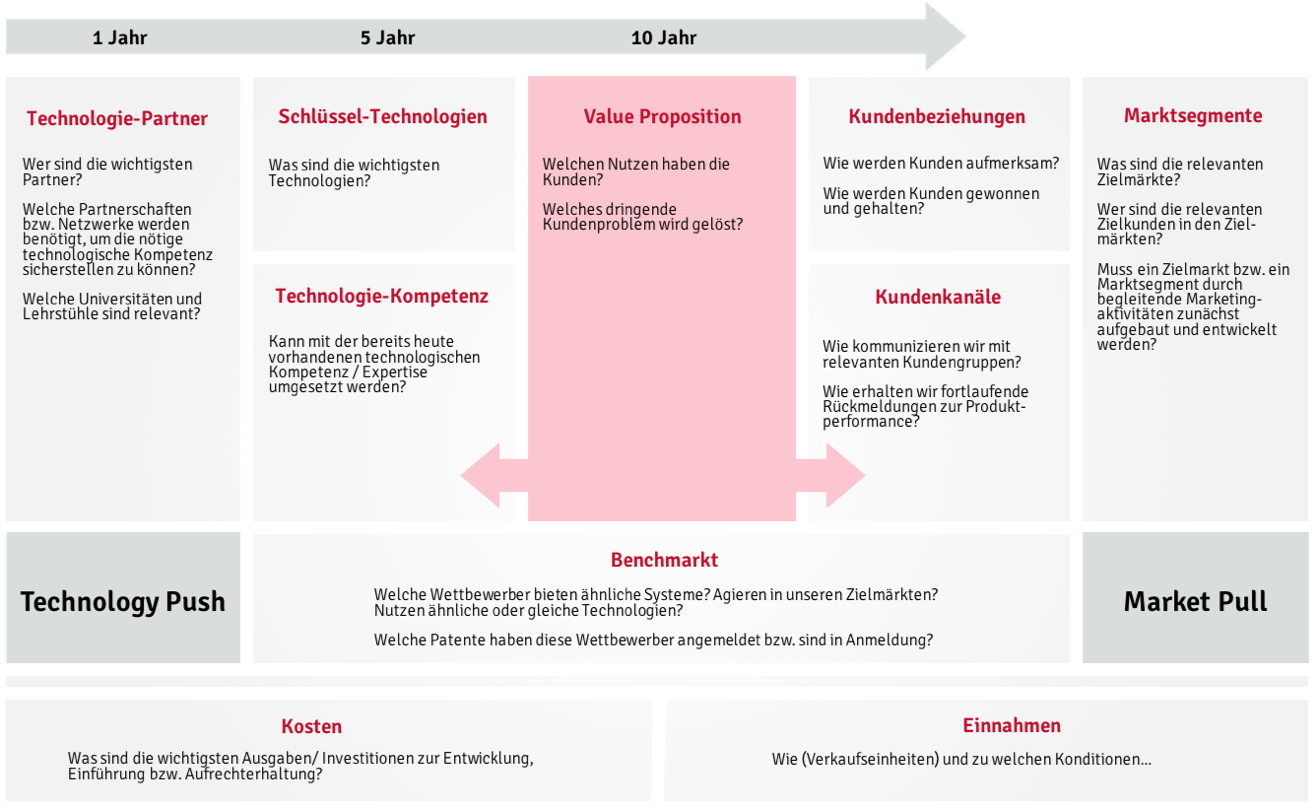

DfSS can be used for re-designs and new designs and follows a step-by-step procedure, the so-called DMADV phase model. It stands for Define, Measure, Analyse, Design, Verify and provides a clear and reproducible thread in the project work and thus ensures efficient use of resources.

Design for Six Sigma with DMADV focuses on essential development elements such as relevant target customers and their requirements, condensing needs into measurable requirements, deriving and evaluating alternative rough concepts, deriving detailed designs at product and process level and preparing for a market launch or a step-by-step roll-out. A red thread overview:

Define – project launch:

What opportunity does the innovation project offer for the market and the company, how can it be transferred and delineated into meaningful project structures, and what external and internal environmental factors need to be taken into account?

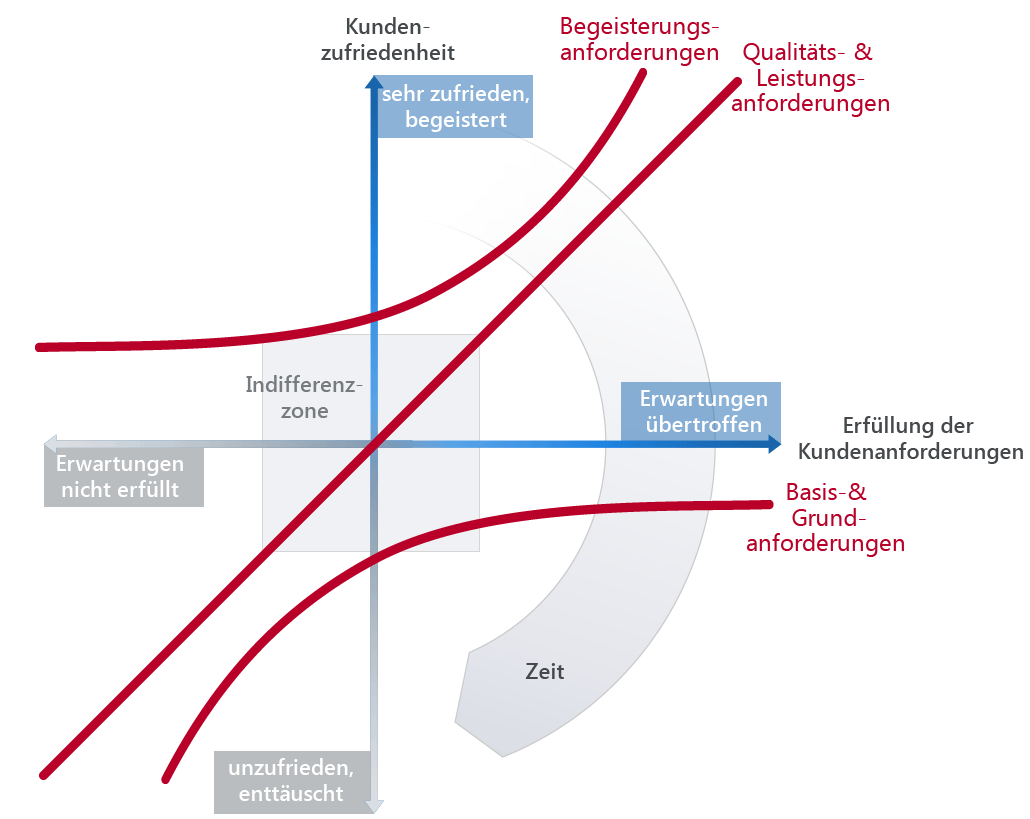

Measure – Manage requirements:

Which markets and customer groups (external/internal) are relevant for the project, which channels can be used to gather needs and how can relevant requirements be determined, specified and quantified from this?

Analyze – derive design concepts:

How can requirements be transferred into first alternative design concepts and supplemented with further innovation impulses, how can continuous customer interaction be enabled and which process requirements have to be considered besides product development?

Design – Developing enemy designs:

How can the design concept be developed into a detailed detailed design for products, processes and services, do existing processes, procedures and structures have to be adapted and which activities have to be initiated in marketing and sales?

Verify – prepare for market launch:

What results do test runs/pilots/field tests show, does the design fulfil the project-relevant customer requirements and how can a market launch be reliably prepared?

What are the advantages of Design for Six Sigma?

It takes project teams “by the hand” and ensures that they start with a clear mission and a common understanding of the content and direction of the project. Relevant target customers are actively involved and their needs thus become the central basis for further innovation work.

The focus is not on the detailed elaboration of tools and methods, but on answering essential guiding questions for the step-by-step shaping of ideas and thus still offers the necessary creative degrees of freedom during implementation.

Agile development approaches can also be integrated into the individual phases of the process, for example, in order to achieve initial valid results quickly and with direct customer feedback.

Acceptance, trust and motivation for a method are central objectives for us – we implement these requirements with a didactic mix of instructional talks, group work, simulations and exercises. We integrate concrete innovation and development projects into the training and provide the necessary “vision”. How can established topics be usefully supplemented by new technologies, systems and possibilities – for this purpose, we organise corresponding expert talks on advanced topics (e.g. process mining and AI in the design context) in the context of the training and participants experience how what they have learned can be supplemented and strengthened by modern approaches. They test relevant systems and tools and thus gain a very individual “vision”.

Two of our consultants are considered leading experts in Lean and Six Sigma in Germany and are co-authors of the standard work in Lean and Six Sigma.