Design lean,

waste-free processes

- View and understand processes holistically

- Evaluate processes qualitatively and quantitatively

- More process transparency

- Being able to unerringly identify optimisation levers

- New perspectives from the combination of information and material flows, process-relevant data and times and analysis options

Values Stream Analysis

What is Value Stream Analysis?

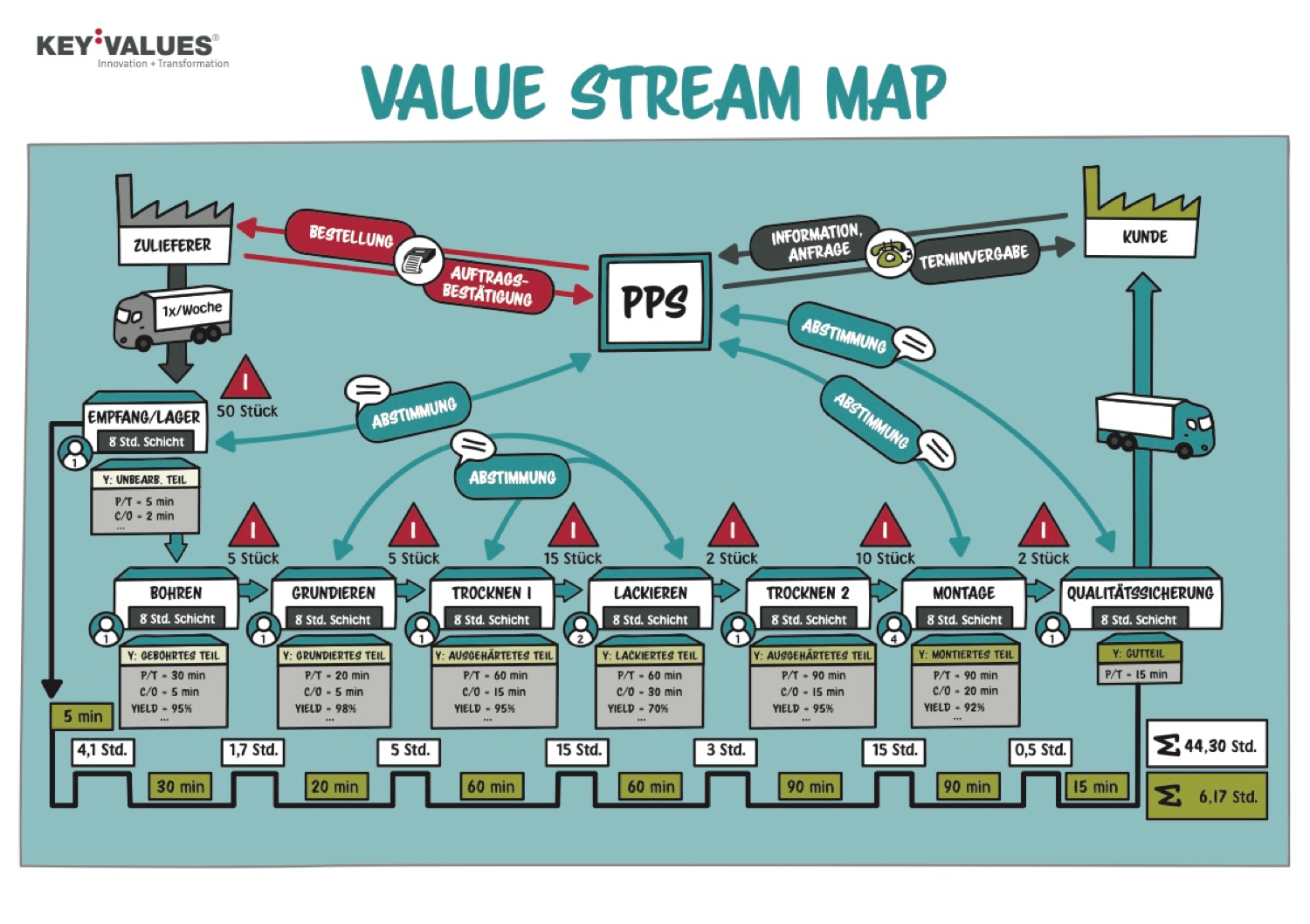

Processes need streamlining and improvement from time to time in order to continue to “do their job” as a value-creating infrastructure. Today’s competitive situation requires companies to permanently optimise their performance and therefore demands a holistic optimisation of value streams across company boundaries. A value stream analysis is a targeted method for recording and presenting relevant information and material flows.

It forms the basis for a better understanding of processes and is the navigator of targeted improvement.

What does Value Stream Analysis involve?

A Value Stream Analysis brings together qualitative and quantitative perspectives in order to visualise and understand processes in a more targeted way. The jointly developed current state forms the basis for identifying weaknesses and waste in value streams, simplifying information and material flows and ensuring process transparency. However, an analysis also offers the possibility to identify targeted optimisation levers, as the combination of qualitative and quantitative perspectives can show which concrete measures are necessary to eliminate a bottleneck.

The results of an analysis thus help to make optimisation potential visible and quantifiable. Our training teaches both the procedure and methodology as well as further analysis perspectives for an appropriate process design and for deriving a TARGET state.

What are the advantages of Value Stream Analysis?

Value Stream Analysis is a very effective tool for driving forward improvement activities in your own company.

- Actual processes are recorded, visualised and explained with material and information flows

- However, actual processes are also experienced and evaluated at the “place of action

- On-site process inspections provide the necessary qualitative counterweight to key figures and parameters from ERP and PDA systems

- Control concepts in existing systems are recognised and recorded

- Key performance indicators and process characteristics (e.g. throughput time, capacities, stocks, waste shares, etc.) are interpreted and existing bottlenecks in process chains for an optimised process design are specifically addressed

- The recording also forms a basis for further modelling in appropriate tools and systems, in order to be able to transfer the recorded value stream into a process simulation if required

Our workshop also shows how the approach can be transferred to administrative areas and how a concrete recording, representation and analysis of administrative processes can be carried out.

However, we will also show how a Value Stream Analysis should develop further in today’s companies, since necessary process and customer data are regularly the actual bottleneck. In order to overcome data bottlenecks, however, a Value Stream Analysis with ERP real-time data can have a completely different effect as a kind of “digital twin”:

- an ERP-based image of central value streams

- bring data-based process knowledge into the teams more quickly and thus look at cause-and-effect mechanisms in a more targeted way on the basis of real-time data

- visualise relevant value streams, lead times and bottlenecks in a data-based manner and, for example, understand and improve on-time delivery, critical supply chains and planning processes

- Reduce KPI systems to the “few important” parameters and build a real-time management cockpit

- Expand process knowledge with a data-based roadmap of the right “levers” for improvement

For this purpose, we show tools, systems and possibilities to enable “foresight” here as well.